According to the EU Directives for phasing out all the member states' Coal-Fired Power Plants till 2030, we strongly believe :

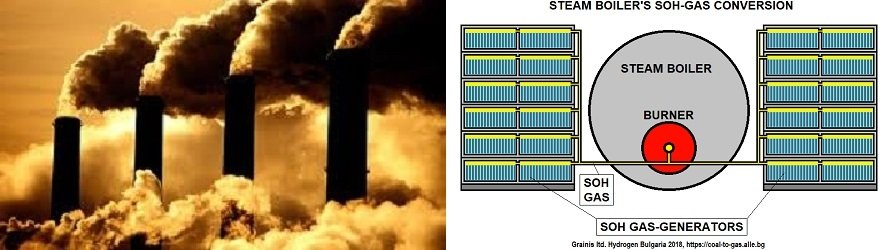

Every Coal-Fired Power Plant (CPP) could be easily converted to burn Clean SOH Gas, at a cost, close to zero.

Alongside with producing Power and Heat, the Plant could produce also :

-- MOH Gas Fuel, - 100% storable, clean, renewable,

-- Pure Hydrogen Fuel and

-- Basalt-Fiber Composite Materials.

CPPs are very expensive, billion-euro assets and we do not assume their closing reasonable at all.

We strongly believe there are ways for these Plants to be easily converted into clean processing and to work more decades ahead, even with times larger profit than now.

Till that happen, the CPPs could capture the CO2 and CO outlet gases, and to combine them with low-cost Hydrogen through the Fischer-Tropsch (FT) Cycle for production of numerous valuable Hydrocarbons as Diesel, Gasolie, Methanol, Ethanol, DME, Methane, Ethylene, Propylene, etc.

The Coal from the Coal Mines could be also used ahead as a Carbon Raw Material for producion of demanded Methanol Fuel , etc. thus reaching a strong social effect by keeping all the present miners' jobs operative.

Who are wе and what we do.

Grainis ltd. Hydrogen Bulgaria is a small Bulgarian R&D company.

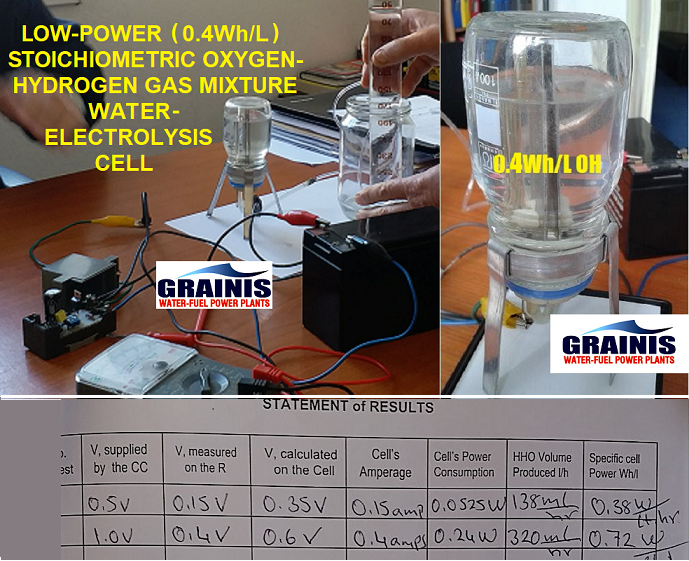

Our team works since 2005 on projects for low-cost Hydrogen and Hybrid-Hydrogen / Stoichiometric Oxygen-Hydrogen (SOH). Ultrasonos-Modified SOH (MOH) Storable Gas etc. production by pulse-peak current-modified low-power water electrolysis (LPWE).

Starting from the desperating 9Wh/L and huge ineffective equipment in 2005, after 15 years of hard work now we have a special small & compact, unlimitedly-multipliable electrolysis cell and a unique method, producing SOH gas with 0.4Wh/L (0.9kWh/kg) and pure hydrogen with 1.1Wh/L (12.3 kWh/kg) power, which makes the cost of the on-grid production less than one dollar per kg H2 (compared to the $10/kg H2's average market price), and less than $0.10/kg SOH/MOH.

Off-grid, self-powered gas production will be even cheaper.

SOH's cost is much lower, because it needs 9 times less power per kg for its production ( H2's Molar Mass is 9 times less the SOH’s).

We use special electronic devices (PWM, PSM, PPM, etc.) for distributing the current supply into tiny shock pulses of about 1 millisecond each, followed by ~99ms “silent” period with NO power supply, but with still continuing gas production, thanks to the previous electrodes' polarizing charge by the shock pulses.

These cycles are repeated about 10 times per second.

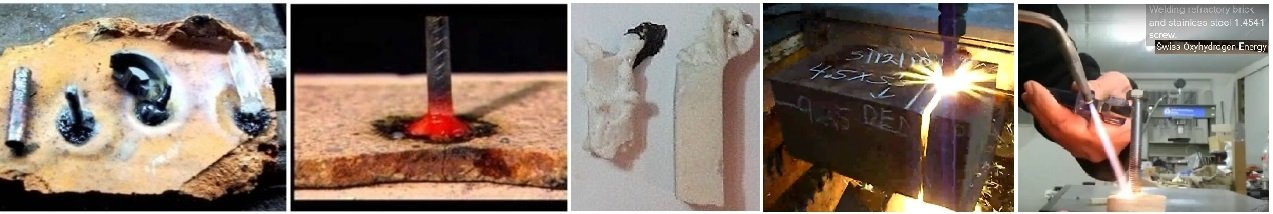

SOH Gas performs unique thermal properties.

It's gas-plasma ( electro-conductive ionized gas ) flame is uniquely cold - only 140deg.C, but it heats up some UHTC ceramics as ZrO2 and Ta4HfC5 over 6,0000C ( being only 1400C hot itself).

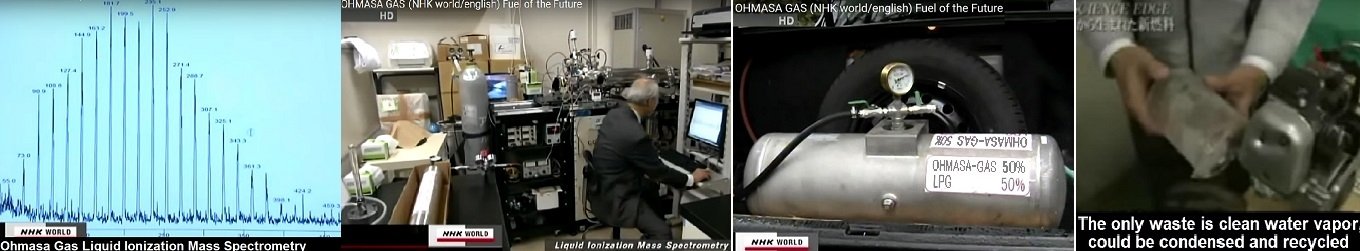

We have also experimented with the Stoichiometric Ultrasono-Modified Oxygen-Hydrogen (MOH, MHHO) gas, patented in 2011 by Dr. R.Omasa from Japan, as Ohmasa Gas.

http://www.patentsencyclopedia.com/app/20110139630#ixzz3LOxSiPwy ,

https://www.youtube.com/watch?v=NUPE0Z9V82E

https://www.youtube.com/watch?v=nVwmr7WNtNA - heating office buildings in Tokyo with MOH/Ohmasa gas

Unlike the regular SOH gas, MOH/Ohmasa can be compressed over 200 and 700bar, liquefied at 1bar/-1780C, filled and stored in CNG/LNG bottles for years, and shipped everywhere.

MOH is denser than H2 - 1m3 of liquid MOH contains 167kg of H2, vs 70kg of H2 in 1m3 of liquid H2 alone, or 2.5 times more.

MOH is an ideal universal direct-injection fuel for all kinds of ICE's and Gas-Turbines, and an excellent H2-storage. Pure H2 and O2 could be extracted out of pressurized or liquefied MOH gas, on-board, on-demand and used for fueling HFCs.

MOH cannot be ignited by a spark and doesn't perform leakages, permeation, diffusion and embrittlement as the pure hydrogen does.

MOH can be burned in standard Gasoline Engines, Gas-Turbines, Rocket Engines, Steam-Boiler Burners.

It's gas-plasma flame heats some UHTC ceramics as ZrO2 and Ta4HfC5 over 6,0000C ( being only 1400C hot itself).

Due to these unique properties, we can say, that MOH is the ideal clean fuel and the perfect H2-storage.

COAL-TO-GAS CONVERSION.

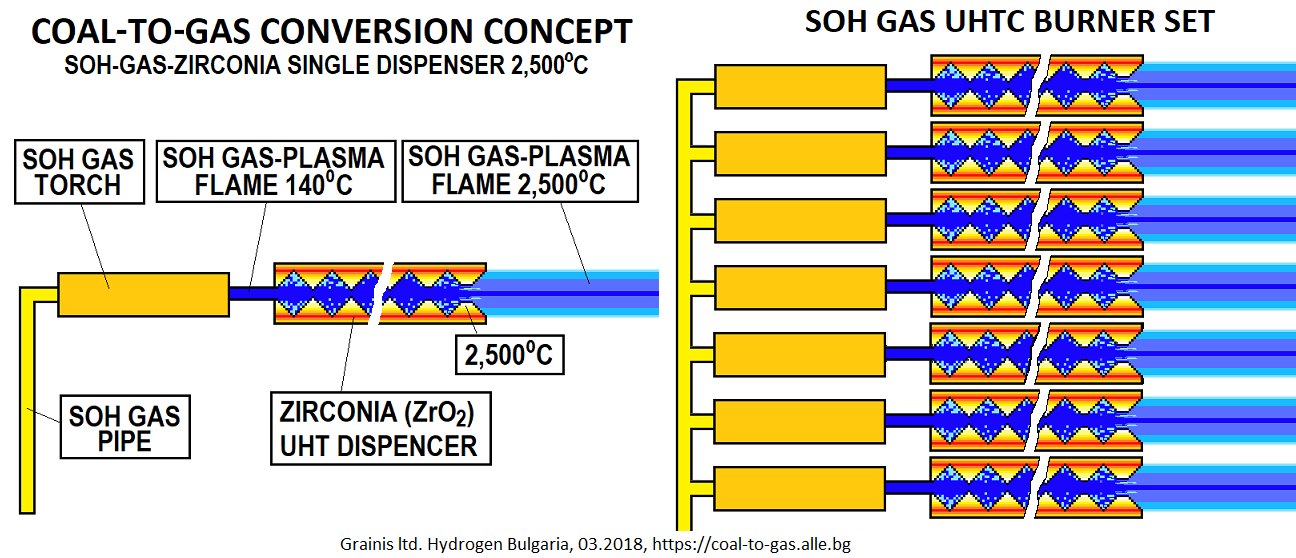

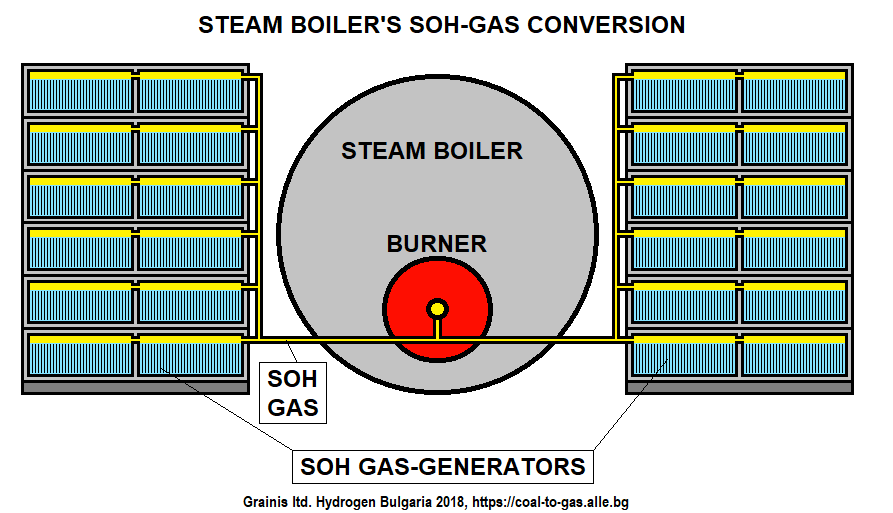

Combining the ultralow-power water-electrolysis SOH gas production, with the SOH gas-plasma flame’s ultrahigh-temperature heating, we can build a SOH Gas Plant, producing 100% clean gas fuel and extreme heat out of water, at a cost, close to zero.

SOH Gas Plant could be installed in every coal or CNG-burning Power Plant and to replace partially or entirely, the existing hydrocarbon fuel used.

A little adjustment of the existing burners and steam boilers must be made, in order the new SOH Gas fuel to be adapted, based on introduction of oxy-resistant ZrO2 , 2,7150 C thermal dispenser which will withstand the powerful oxidizing impact of the SOH Gas and will provide the ultrahigh temperature of 2,5000 C for heating the steam boiler’s water and turning it into overheated steam.

CONTACTS :

Grainis ltd. Hydrogen Bulgaria

5 Gen. Edward Totleben blvd., 1606 Sofia, Bulgaria

cell: +359 899171570 (9AM-9PM EEST)

grainis@abv.bg

grainisbg@gmail.com

https://hydrogen-economy.alle.bg